Production of High-Quality Aluminum Nails for Russia

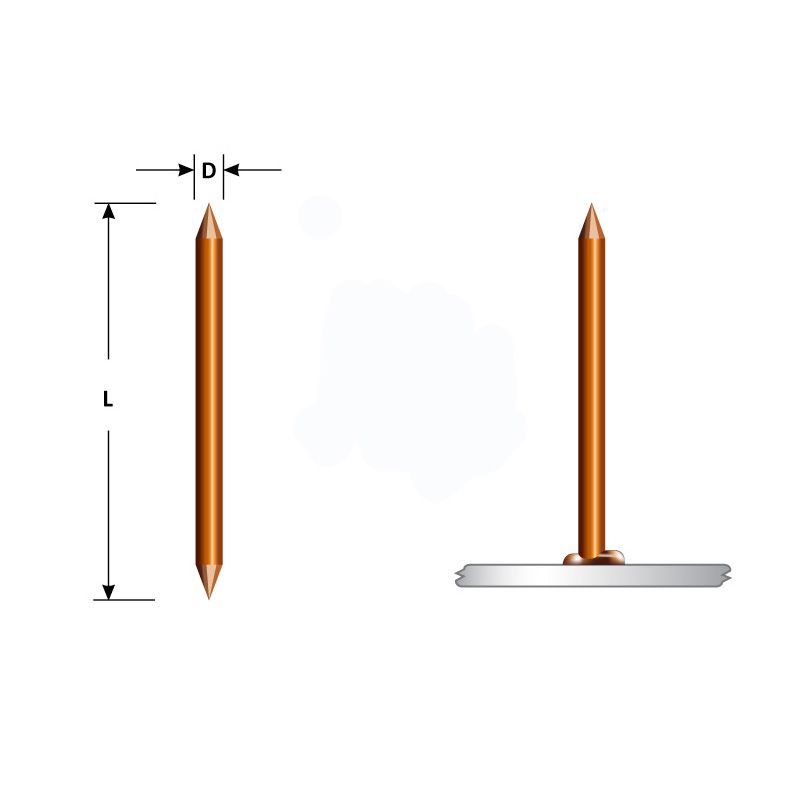

Recently, our company has customized a batch of exquisite aluminum insulation nails for Russia. The quantity of this batch of aluminum nails is 100,000, the size of the bottom plate is one inch, and the length of aluminum wire is 1-1\2 inches.

This is a further recognition of our factory's aluminum thermal insulation nails from overseas. Our aluminum thermal insulation nails have been exported to the United Arab Emirates, Oman, Qatar, Singapore, Taiwan and Hong Kong, etc., and have been generally praised by foreign customers. Its brand has been well-known all over the world.

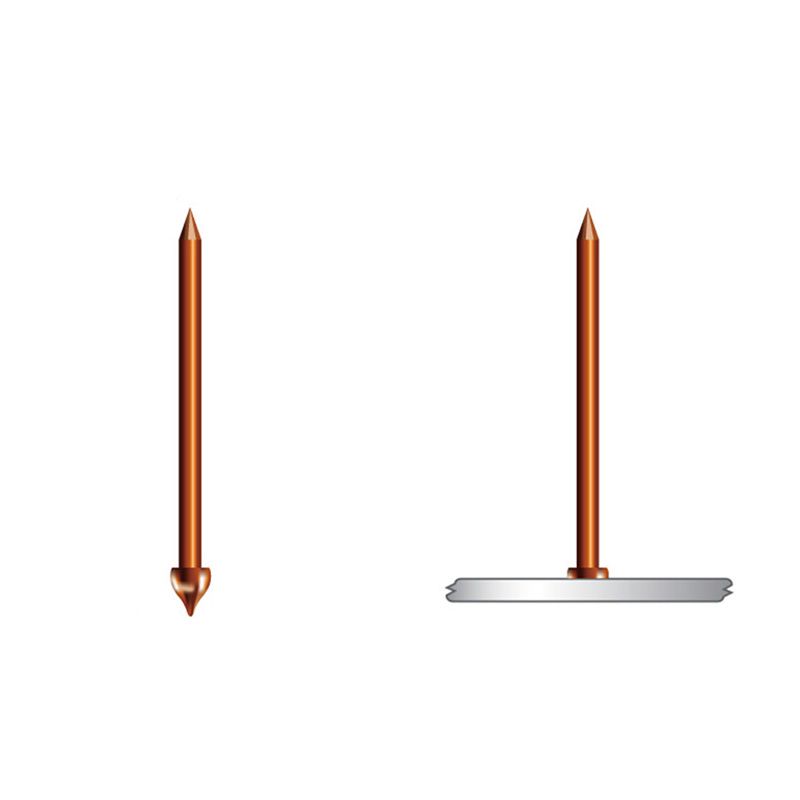

Introduction of aluminum insulation nails:

Aluminum insulation nails are mainly used to fix insulation boards at glass curtain walls and air-conditioning ducts.

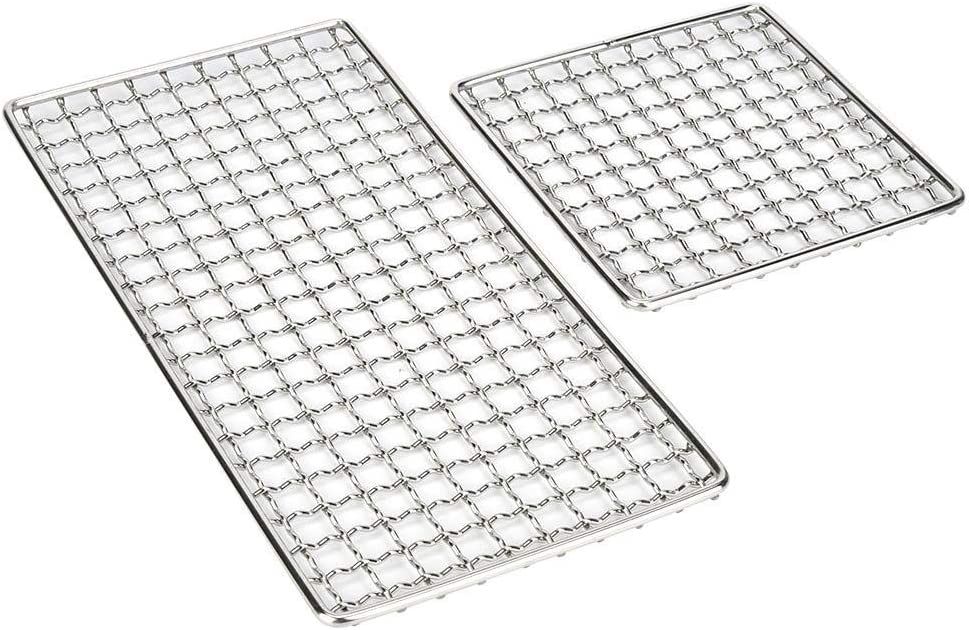

The aluminum insulation nail has a good performance of bearing high pressure, it is not easy to deform, so it is very convenient to install in the construction process. Whether it is winter or summer, there is no problem in fixing the insulation layer, and the insulation layer can be well fixed. Aluminum insulation nails are made of tinplate and aluminum wire riveting. Its specifications are as follows:

1. Ordinary aluminum insulation nails:

The current specification of ordinary aluminum insulation nails is 3.8cm × 3.8cm × wire length 1.35mm × wire length 16mm. This type of insulation nail is often used to hang welded wire mesh when painting interior walls.

2. Aluminum insulation nails for air conditioners:

The aluminum insulation nail for air conditioner is made of good galvanized sheet and alloy aluminum wire riveting. Paste the glue.

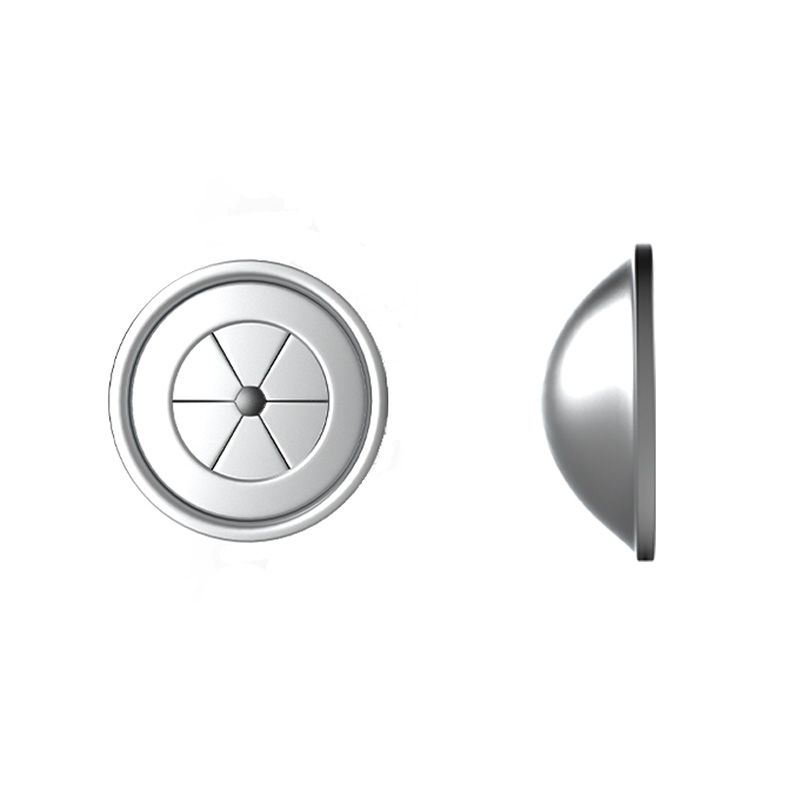

3. Aluminum insulation nails for glass curtain wall:

The aluminum insulation nails for glass curtain wall are made of good galvanized sheet and alloy aluminum wire riveting. The specifications are 5cm × 5cm × wire length 2.5mm × wire length 50mm.

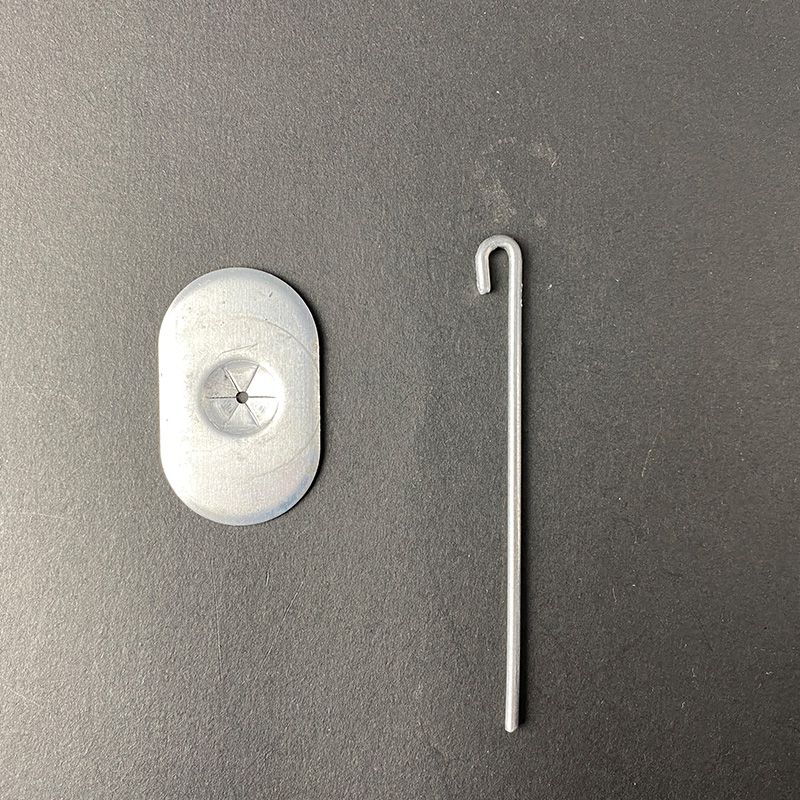

4. Double-sided adhesive insulation nails:

The double-sided adhesive insulation nail is made of good galvanized sheet and alloy aluminum wire riveting, in the process of use, just peel off the outer layer of the double-sided tape and fix it directly on the surface to be pasted.